JVP raised floor:

where it is used

Applications of our flooring system

Designing in a new way, right from the start.

Reducing static load on each floor by at least 120 kg/m2.

Making floor systems available for inspection.

The accessible raised floor is known as a technological dry screed. It is now being used in new ways and with cutting-edge design techniques for all kinds of buildings. Metal, wood, reinforced concrete or mixed floors all have a structural, weight-bearing part and a non-structural part for other functions.

The structural part must bear its own weight as well as the additional non-structural part of the ceilings of the storey below, system slabs and floor screeds, the floor itself and the people and things resting on the finished floor.

The non-structural part greatly influences floor calculations as well as seismic calculations: the lower the total weight, the simpler and less expensive the load-bearing structures can be, starting from the foundations.

To reduce costs, construction time and raw material consumption, we need to change our design approach to lighten and simplify flooring.

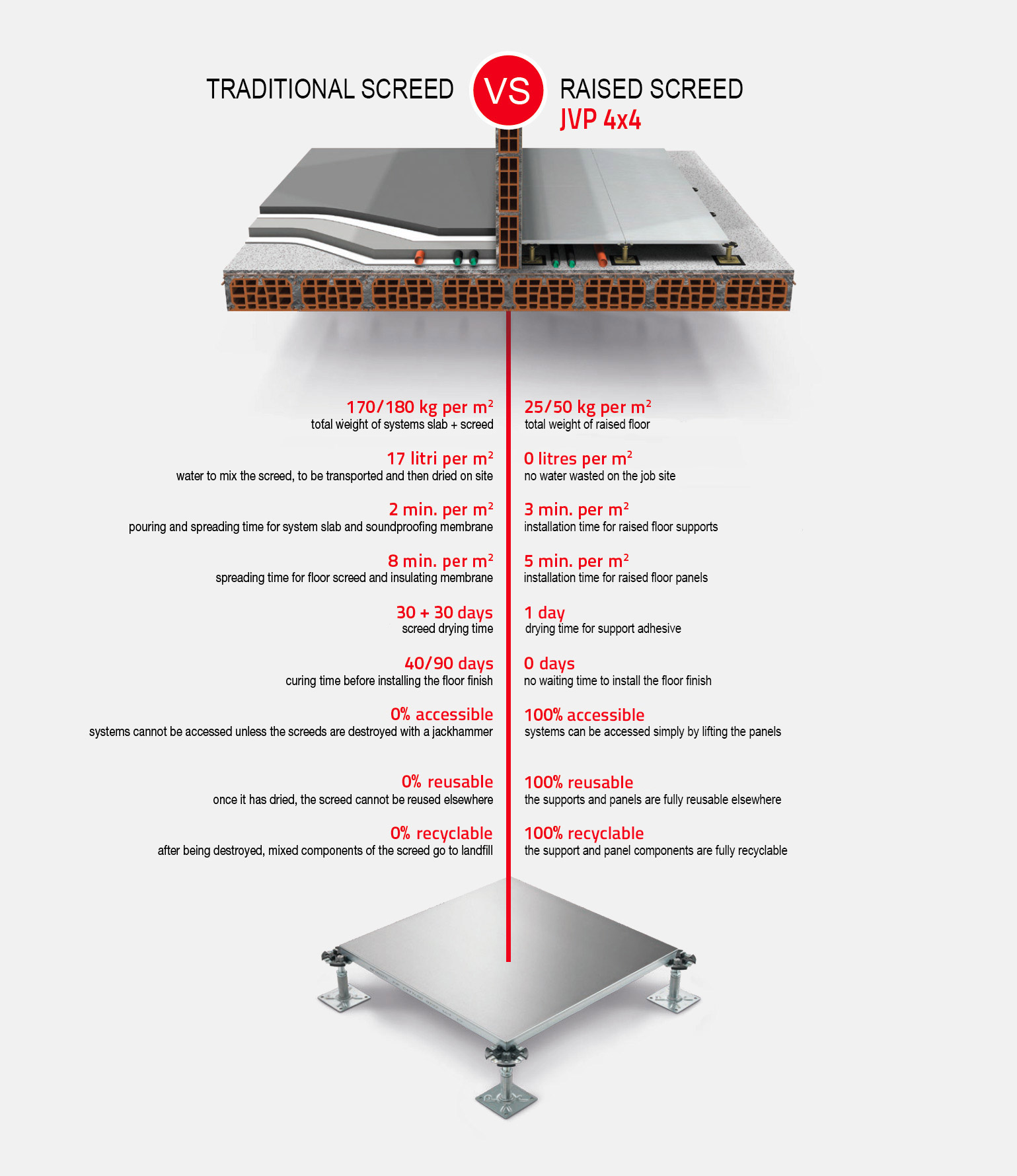

JVP proposes eliminating wet sand and cement screeds for systems and levelling screeds, acoustic, thermal and vapour barrier sheaths, thereby eliminating at least 8 + 3 cm of thickness and 170 kg of weight per square metre.

JVP also replaces screeds right from the design stage with a single inspectable element, that guarantees all system space functions, floor levelling, smoothing floor installation, soundproofing, thermal insulation and vapour barrier, with minimal costs and weights.

This is JVP 4×4: it weighs no more than 45 kg and reduces weight by at least 120 kg per square metre of floor space.

JVP proposes eliminating wet sand and cement screeds for systems and levelling screeds, acoustic, thermal and vapour barrier sheaths, thereby eliminating at least 8 + 3 cm of thickness and 170 kg of weight per square metre.

JVP also replaces screeds right from the design stage with a single inspectable element, that guarantees all system space functions, floor levelling, smoothing floor installation, soundproofing, thermal insulation and vapour barrier, with minimal costs and weights.

This is JVP 4×4: it weighs no more than 45 kg and reduces weight by at least 120 kg per square metre of floor space.