JVP raised floor:

how it is made

Creation of our flooring system

360 square meters of flooring are produced every hour.

3,2 seconds

to produce one panel.

to produce one panel.

0,015% of panels discarded during production.

Raised flooring is very robust to withstand the difficult conditions of the construction site, and then daily use.

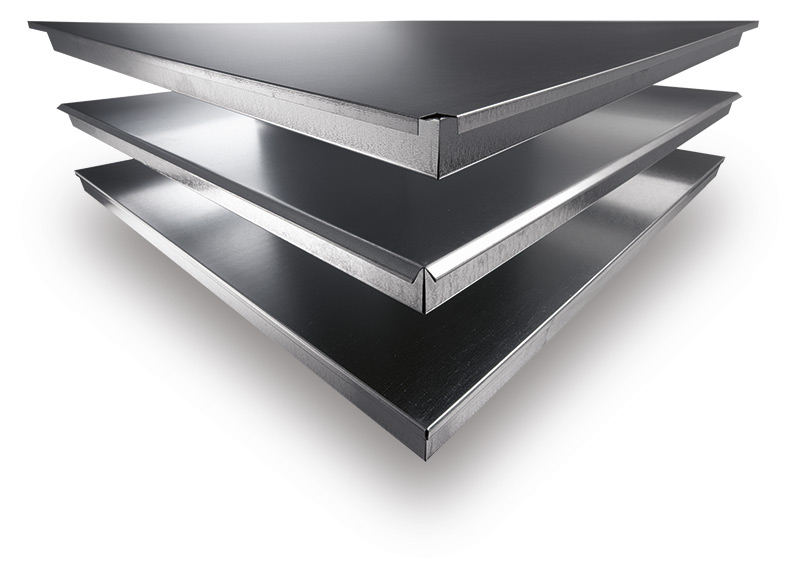

To stand up to the rigours of the construction site, we have chosen a heavy-duty and fully recyclable galvanized sheet metal casing.

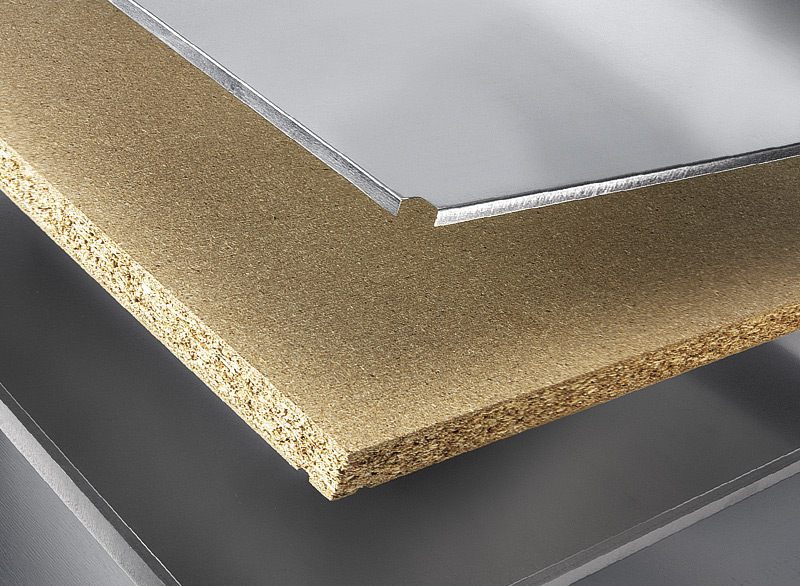

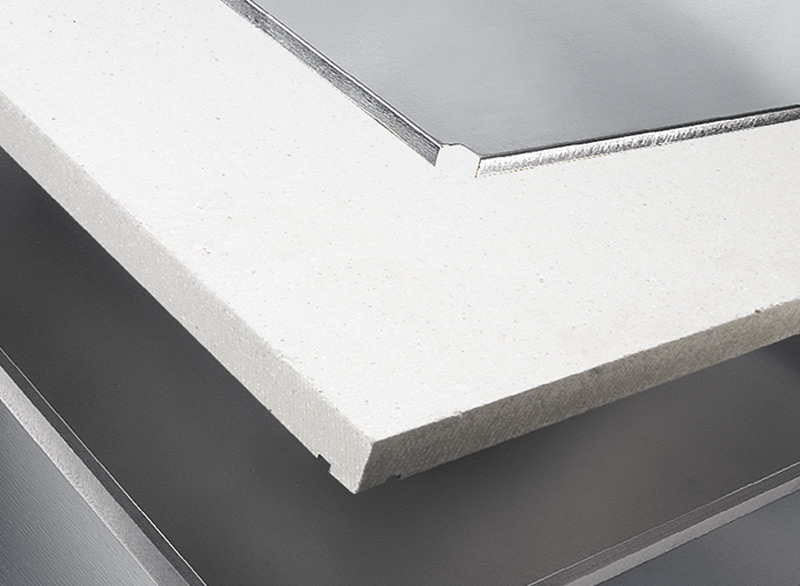

For mechanical loading capacity, we have chosen to use internal panels made of certified wood chipboard or fibre-reinforced calcium sulphate glued to the sheet metal, which are highly resistant to bending and breaking.

To close each panel, we have borrowed the idea of double-seams from food cans, so our panels already have a peripheral “beam” that eliminates the need for additional cross-pieces.

The JVP 4X4 panel is ready in three steps: a simple, effective and innovative idea in the finest Italian tradition.

JVP’s plant is a third-generation production line designed entirely by JVP’s technical staff in 2002, updated in 2017 and as fast and efficient today as any in the industry: come visit us or check out our photo gallery.